- Sales hotline

+86-512-62653308

No.6 Qingqiu Street, Industrial Park,

Suzhou, Jiangsu Province, China.

Laser power:

Laser power:

Processing width:

Processing width:

Dimension:

Dimension:

Cutting material and thickness:

Cutting material and thickness:

Line width:

Line width:

Maximum scribing depth:

Maximum scribing depth:

Repetitive positioning accuracy:

Repetitive positioning accuracy:

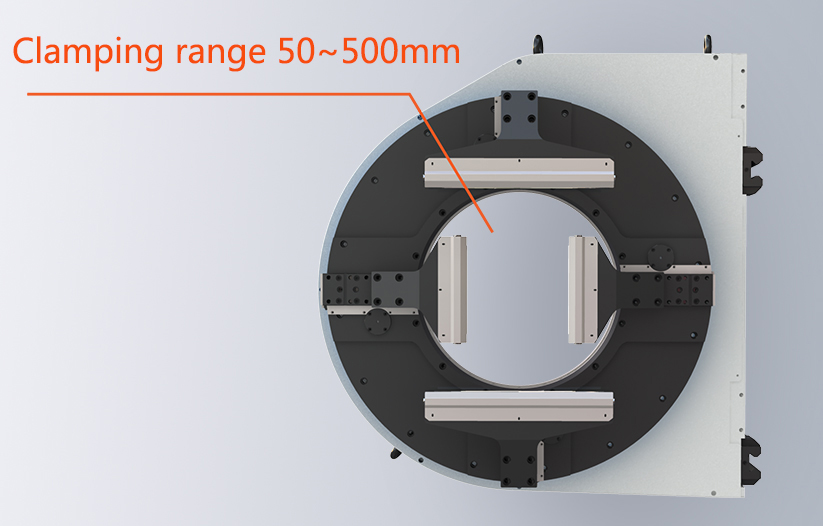

Clamping range:φ50-500mm

Clamping range:φ50-500mm

Independent design patent chuck

Independent design patent chuck

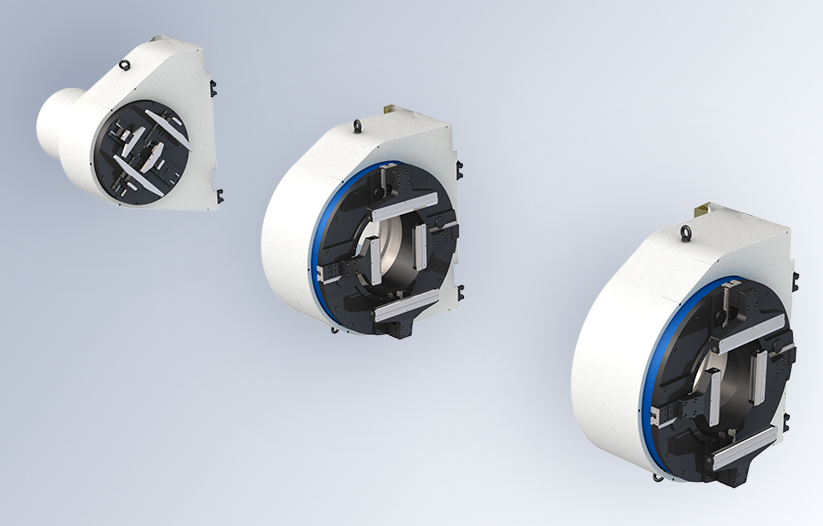

Three chuck structure design, high efficiency

Three chuck structure design, high efficiency

Zero tailing cutting without waste

Zero tailing cutting without waste

Whole pipe feeding and whole pipe blanking

Whole pipe feeding and whole pipe blanking

maximum power:20000W

maximum power:20000W

Inquire Now >

Inquire Now >

Independently developed and patented chuck has simple and stable structure, good sealing and motion characteristics, and can clamp square tube, round tube, elliptical tube, I-beam and other materials.

The three chuck processing mode meets the cutting head to cut the tail material between the two chucks, so as to improve the cutting accuracy of the tail material. With the high efficiency and high-quality processing performance of different shapes and specifications of pipes, QUICK LASER’s radium laser pipe cutting machine is widely used in many industries such as fitness equipment, automobile manufacturing, temperature keeping containers, office furniture, agricultural machinery, high-altitude operation, hardware products and so on.

Ultra Heavy-duty Laser Tube Cutting Machines—50BK Series Characteristic parameter

| Property / model | FCT12050BK |

| laser power | 1500W-20000W |

| Machining dimension of round tube | φ50-φ500mm |

| Square tube processing size | □50*50-350*350mm |

| positioning accuracy | ±0.05mm/m |

| Repeat positioning accuracy | ±0.05mm |

| 10. Maximum positioning speed of Y axis | 60m/min |

| Chuck speed | 40r/min |

| Maximum mass of single pipe | 1000kg |

*All technical parameters shall be subject to the latest technical scheme。